October 28, 2010

What's changed in 5,000 years of traditional broadhead design? Remarkably little.

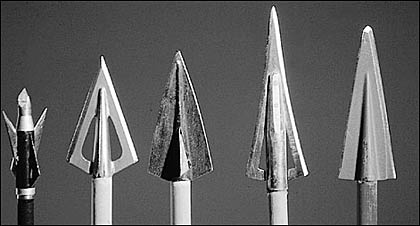

The mechanical Gold Tip, far left, is well designed of the finest material. That any such head is more accurate than the more standard style, however, is hard to prove, according to the author. Continuing from the left are the Zephyr Scirocco, MA-2, Howard Hill three-to-one design and the 160-grain Grizzly. On following page (bottom): the Steel Force 100-grain, by Ballistic Archery, represents the very latest in cut-on-contact design. |

The Ice Man captured our imagination. ItÂ's nearly impossible to put the 5,300-year-old bowhunter out of mind, probably because traditional archers have so much in common with him. Found in the Italian Alps with bow and arrow intact (bow broken in recovery), Otzi, as he was named, had broadheads and a knife of stone, although his axe blade was copper. If he could make a metal axe, why stone broadheads? Sharpness! To this hour, a properly knapped stone head is sharper than a razor blade. The Native American archer also found stone heads worthwhile--until Europeans crossed his path. Flint, chert, jasper, obsidian, basalt, agate--all became deadly broadheads. Ishi, last of his northern California tribe, showed Dr. Pope how to craft stone heads.

Primitive broadhead makers were expert at their trade, chipping away until they had an excellent product. This took skill and experience; skill in pressuring flakes off to create a specific shape, experience in getting good broadheads every time. In effect, the stone head was as deadly as any steel example we have. But it was abandoned for one major reason--breakage. IÂ'm told by those who know that Plains Indians made broadheads from wagon wheel hoops left behind by settlers heading west. Steel heads didnÂ't require long practice sessions nor a keen hand. Almost anyone could do it, and the head didnÂ't break after one shot.

Advertisement

One afternoon as I hiked the high desert of central Wyoming, I shot an arrow across a sandy draw, something I do often when still-hunting. The friend I was with withdrew my arrow from the sand, reaching down at the same time to pick something up. It was an Indian stone arrowhead, lost there--who can say how long ago? Because he had a collection and I didnÂ't, my companion kept it, but I had a curious feeling about it the rest of the day. An archer of long ago shot an arrow into that same sand bank, losing the point, or perhaps the entire arrow, the shaft decaying to leave only the stone head behind. Stone heads remain legal in some areas, illegal in others. But they are without doubt the forerunners of our traditional-style broadheads.

Original steel heads were shaped a lot like stone points, generally not as complicated, certainly nothing like those found in IllinoisÂ' Cahokia Mound, with serrated edges and varying contours. When Pope & Young took the archery trail, hand making tackle was common, including steel heads. Some were barbed, meaning they had "tails" that prevented the head from falling out. It was inevitable--mass production of steel heads had to happen. It was a market waiting to be tapped.

Advertisement

Broadhead design was wilder in the late 1800s and early 1900s than it is today. Every designer had his own theory. Howard Hill believed in the three-to-one style, the head being three times longer than wide to promote penetration. Roy Case of Case Broadheads proved otherwise, backing up Forrest NaglerÂ's earlier concepts. Case and Nagler were big in bowhunting in the early 20th century.

When Zwickey came out with its state-of-the-art broadhead, it followed the Case/Nagler concept. The company couldnÂ't make enough at the time because bowhunters found them absolutely deadly, just as they do today. However, Fred BearÂ's famous Razorhead nearly wiped the Zwickey off the map, not because it was better, but because it worked and Fred found a way to make thousands of them fast. I remember buying them for two reasons: They sharpened readily, and they were inexpensive.

Before Zwickey and Bear got busy, the chariots of invention were already racing down the road, dust boiling from their innovative wheels. If it could be imagined, it could be made, and some imaginations ran wild. Most claims were easily proved too. Why? Because heads were effective with "boiler room" hits--if they were sharp.

While it may seem odd, the vital criterion of dispatching game quickly was really not most important. In effect, an archer could fix pieces of broken shaving blades to an arrow and kill a deer, which did not prove that they made a great broadhead. Other criteria were more important: accuracy (along with wind planing) being first on the list, followed by reduced drag through design, strength and sharpening ease.

This Kentucky doe was harvested with a 160-grain Grizzly broadhead from a Black Widow 57-pound bow. The strength of the broadhead made a difference when it hit bone and was not stopped. |

One-piece, two-edge broadheads wind plane, right? Wrong! This bit of pap has been spread like peanut butter on tuna sandwiches for years. Ill-made one-piece two-edge broadheads can wind plane. Good ones do not. This brings us to accuracy, which is a function of aerodynamics and symmetry. Make an unvented broadhead so wide that it works like wings, and wind planing may result. Likewise, an asymmetrical broadhead wonÂ't be accurate. A rotating shaft reduces some of this problem, just as a rifled barrel equalizes lopsidedness in a patched lead round ball. The difference is this: The rifled barrel rotates the round ball hundreds of revolutions per second, making it spin like crazy so that imperfections are equalized on a common axis. The arrow does not spin that fast, so it cannot overcome a lopsided broadhead.

Broadheads like the Zwickey, Zephyr, Grizzly and others of this family do not wind plane because they are not built like airplane wings; they do not create an airfoil. And they are precise in manufacture, which is easily proved by mounting them on a straight shaft and spinning the arrow. I know these heads donÂ't wind plane, and I know they are accurate, because IÂ've shot them from a shooting machine--all human elements removed. Groups were amazingly tight. While modern one-piece two-edge heads with wide blades are vented to eliminate wind planing, this is nothing new. Ben PearsonÂ's 1965 Deadhead, what I call a "hatchet" with its wide cutting swath, were vented.

Drag is another important factor in broadhead design. Some of the deadliest-looking inventions didnÂ't work because they lacked penetration due to excessive drag. A good example is the 1968 alteration of the Pearson Deadhead called the Biscuit Cutter. A third blade was added for more cutting area--great idea--but from a modest-w

eight bow, penetration was cut down by the extra drag. Before that, in 1950, a head called the Excaliber 45 came along, with spiral blades. It was especially effective for coring apples because it cut a circle. Unfortunately, deer arenÂ't apples, and the head failed to penetrate.

Archery is an old game filled with thousands of inventions. I chuckle at the "new" mechanical heads--about as new as the bicycle. The Hinged Fang came along in 1948. In principle, our mechanicals work just like this odd-looking creation. Upon striking, two blades popped into play. Sound familiar? The Red Bow CompanyÂ's Star Point, born circa 1953, was even more bizarre with its pop-out blades. I have no problem with mechanicals with certain bows, but when told they were invented for accuracy, I shake my head. The idea is a target-shape point in flight that turns into a broadhead when the arrow hits. Unfortunately, these new heads proved no more accurate from the shooting machine than a 160-grain single-blade, two-edge Grizzly.

Strength has always been a vital factor in broadhead deadliness because if the head bends or breaks when itÂ's supposed to be penetrating its effectiveness is obviously impaired. As Roger Ascham pointed out in the 1500s, "The Trojans had heads of iron." ThatÂ's how long ago strength was given consideration.

ItÂ's also nice to have a head that can be sharpened by the common man. Single-blade two-edgers are easy to sharpen. The Truangle Traditional Broadhead Hone makes the job simple, although it takes a little wrist-gyration to ensure that the length of the edge meets with the in-place files. The same company makes a hone for what we call bodkin heads, like the Snuffer. Bodkins were actually smallish metal heads used to penetrate mail/armor worn by knights of old.

Over the years, two main edge types have emerged: smooth and wire. Saxton Pope wrote in The Adventurous Bowmen (about bowhunting Africa), "As for me, IÂ'm going over to the hut yonder and take out a little carborundum stone and whet up a dozen fine tempered steel rhino heads, six inches long and like daggers." IÂ've taken game with smooth-edged heads, but prefer wires, the latter created by stroking a sharp edge with a file, or taking a swipe or two with a handheld Bear sharpener. A round diamond sharpener can also raise tiny ridges of metal that act like serrations that rip as well as slice.

Along with the best longbows and recurves ever produced, bowbenders are equally lucky in broadheads. There will be oddball designs here and there, because man must invent, even if his creations are bizarre. Most interesting is the fact that the simple stone head has not been improved upon all that much in design, although tough steel makes our current models far stronger, and in that sense, more reliable. A look at the Zephyr, Magnus and Patriot, along with the tried and true Grizzly, Razorhead and Zwickey, proves that the old stone design was never abandoned. Many designs simply went from stone to steel.